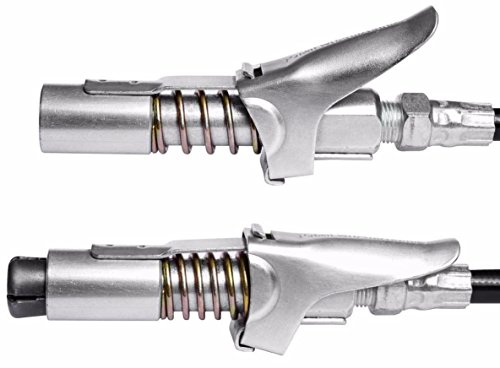

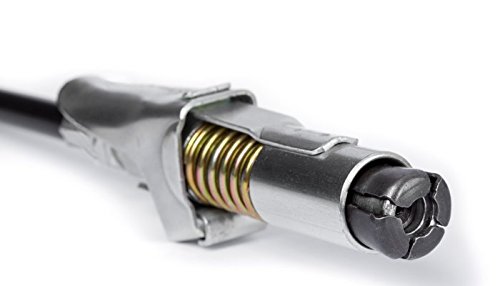

- Locks on, does not leak

- 1/8" NPT compatible with all grease guns - battery, pneumatic, manual

- Grease goes in, not on, the machine

- World's original locking grease coupler.

- World's only rebuildable grease coupler. Lowest lifetime cost.

-

Information

-

Twitter

-

Pinterest

-

Youtube

-

Facebook

Gurwinder Kaur

Awesome Product

I was tired of pulling out zerk fittings or having trouble getting the end of the grease tip on zerk fittings in awkward spots. So I decided to try this product, and am I happy I did. It works as advertised. Makes greasing my tractor, utv and trailers a breeze. I have seen reviews stating that grease got all over the place, this is not the case I had no problems at all. One zerc fitting had a seized ball bearing from dirt and the grease would not inject. I took a pick and some wd 40 sprayed it pushed in the bearing with the pick. Attached the grease hose again and no problem at all. I think many reviews stating grease would not go in the zerc and got all over the place had the same problem. I am going to buy 2 more for my other guns. I am no mechanic and am a casual user I guess, so we will see how it holds up, seems well made. I would highly recommend this item

Samantha Vernon

Makes work easy

My job description might aswell be greaser, I am a service tech for a city, so I grease everything from some cop cars all the way to full sized garbage trucks (Google lodal garbage trucks) this thing makes life easy, while I've found a few fittings that just would not take grease, they wouldn't have accepted grease with or without this fitting, all in all, I will be purchasing more of this product , I would like to see a "mini pistol" version at a 90 deg for even more fittings

Renn Belladonna

WOW Fantastic Tool!

Just received this coupler---WOW is first impression, haven't even used it yet! Very, very well made, feels solid in the hand and looking at the actual locking mechanism it should be quite the tool to eliminate messes during routine greasing operations. Update: Having put this into service I have to agree with myself---great tool! :) In fact its so good I've changed a few Zerks to accommodate its longer length, previously I was using a Lincoln-variant that would swivel for tight areas of which I had a few. Changing those Zerks to 90 and 45 degree fittings gives me full and complete access now. Being able to clip it in place gives me two free hands to power the grease fill, not having to hold the filler in place. It does leave a bit of grease on the end but its no worse than another other filling attachment. Overall I highly recommend this without reservation!

Alfredia Hopkins

Great Addition to your grease gun

Since this product locks to the grease fitting, it makes greasing up my Kub tractor n mower both lots easyer, faster and less messy since the non locking type almost always pops off n makes a mess along with waisting grease. I liked minie so well I ordered 2 extra for my two best friends and gave them away. AND the one buddy lives on the Big Island of Hawaii so one of them is not 5000 miles away and he too loves the ability to lock on the grease line to the fitting. Infact the two photos I posted with this comment were texted to me by the guy from Hawaii when he got my surprise gift in the mail and attached it to grease up his backhoe.

Monalisa Basu

Great for loose zerks

I bought this LockNLube coupler thinking it would help greasing the myriad zerks that stud tractors and some trucks. The coupler worked great, so I bought another one for my other grease gun that has a different grease. Drawbacks: a little larger than a push on / pull off coupler, so in rare instances access is difficult to impossible; somewhat costly; sometimes have to push the handle (spring not strong enough) to keep coupler on zerk, usually due to bad angle of access to zerk. Advantage: you know those fittings that were manufactured just a tad oversize? And the push on coupler just won't pull off without the fear of breaking the zerk off? Not a problem for this coupler. This feature I like a lot. Another advantage: I have a right angle upper ball joint zerk that when tight faces the knuckle-- can't get a coupler on it unless the zerk is loosened by 3/4 turn. Push on coupler generates a lot of cursing getting on and off a loose right angle zerk; this LockNLube is perfect even in the tight space. This ability alone was worth the cost, not greasing a ball joint is a recipe for future expenses. Finally, the LockNLube usually clamps onto the zerk really tightly. A stuck zerk is more easily freed with this coupler than the push on type especially when there isn't leverage to lean on a push on to keep the push on from backing off a little just blowing out grease. Overall this is a worthwhile tool addition. For many easy access zerks the coupler doesn't buy much over the stock push on coupler, but for a significant percentage of the difficult zerks this coupler can save time, effort, and perhaps make the difference between that grease point getting greased or neglected as too difficult.

John Doyle

One of the best tools in my box, and its just a grease-gun tip.

I was skeptical at first, despite the overwhelmingly positive reviews, but I was quickly convinced, this is the single best accessory available for any grease gun. I am a professional auto mechanic, and I pump a lot of grease as part of my day-to-day work. Since I added this coupler to my grease gun (Lincoln 1162, they pair together superbly) I have not once seen any leakage around a grease fitting. I've used this on some dirty, chewed up, caked on fittings, and it still manages to grab firmly and seal perfectly. As others have mentioned, the only issue I've run across is clogged fittings. My Lincoln 1162 pumps at 6,000psi, which will blow open just about any kind of gunk that might clog up a fitting, but once in a while, I find one thats just that bad that I can't pump anything through it. When that happens, I am in a pickle. Even under 6,000psi the jaws of the Lock'n'Lube don't let go. The problem being, if I hit a plugged fitting, and it doesn't free up, the LnL gets stuck on the fitting like a Pitbull, usually requiring a pair of channel-lock pliers to squeeze down the release lever to free the coupler. It is a bit larger than a standard coupler, and it won't fit into every nook and cranny, but I still find it useful in those situations, as it does a great job at holding my adapters and specialty tips in place, allowing me to focus on holding the adapter onto the fitting, rather than holding the coupler onto the adapter. Despite those couple of shortcomings, I still like it better than a regular coupler in every way, and would recommend this to anybody.

Redd Stone

Great Accessory for Milwaukee 2646-20 M18 Grease Gun

The LockNLube Grease Coupler is a great accessory for the Milwaukee 2646-20 M18 Cordless 2-Speed Grease Gun (or the 2646-21CT / 2646-22CT kits). In my particular case, this coupler worked right out the package without any special adapter. However, according to the LockNLube website, certain (earlier) Milwaukee 2646-20 grease guns have a M10x1 threaded end instead of the industry-standard 1/8" male NPT threads. For this situation, they sell a M10x1 female x 1/8" male NPT brass adapter at a reasonable price ($8.49 including shipping). Retrofitting your grease gun with this accessory is simple; the most difficult part is removing the original factory grease coupler from the end of the hose. In summary, this handy device makes routine greasing and maintenance hassle-free. Highly recommended.

Harry Howard

Slick addition for every grease gun. Worth its weight in gold.

This is a fantastic invention. It really works. I added one to my pistol grip manual pump grease gun that has a flexible rubber tube. Push the lever on the LockNLube coupler, snap it on the zerk, release and it stays locked on the grease zerk. Pump your grease with either one hand or two hands on the gun. Then depress the lever on the LockNLube and remove from the zerk and your done. Very slick. So far has locked on to all of my many grease zerks on a variety of farm machinery and tractor. Makes a positive connection and all zerks have taken grease. Used for over two years. Nice it comes with extra seals, but have not had to replace them yet.

Abdul Hamid

Git yerself one a these!!!!

Holy crap folkz! This is one a them thangs ya don't know ya need until ya get it! We're jus simple country folks so we don't have any special need for this thang. We have a lot a trucks and farm equipment and we try ta keep to a maintenance schedule on em. That is every six months we go out an grease thangs whether they need it or not. Not only that but one a my sons has developed a maintenance business of his own where he goes out ta peoples houses and greases their equipment and checks it out and does small engine work. He says he uses this thang almost ever time he goes out. Now we could use our hand ta hold th fittin on the zerk but that gets old and sometimes ya got them thangs up in places that hard ta get to. If ya can grease it ya can get this thang over th zerk. We ain't found one yet this wouldn't fit. We've just bought a Lincoln grease gun and we're gone write a review on that soon. Now we could'nt justify buyin one a them power grease guns...have ya seen th price on em. So any a you people gripin about much this thang costs are welcome ta go buy a power gun ta make life simpler. We fall in that category where we need somethin ta make our job easier but we don't want ta be haulin around th air-compressor because it just ain't worth it. If you think it's aggravatin ta grease yer machinery then yer probably gone love this thing . And it's well made. This is a real tool. Th grease goes in th joint not everywhere else. If ya want yer greasin ta be simpler and easier get yerself one a these. Holy s***! I almost did a entire review without cussin.

Jerre Neeley

Awesome little attachment, definitely worth the $

I bought a pneumatic grease gun for the first time as I had recently installed something with zirc fittings for the first time. Doing a little reading it sounded like pneumatic is the way to go considering the forces that have to be dealt with (I got the cheaper OTC gun which seems to be great). Considering that my car is very cramped (VW Golf R) and that even if the fittings were in an easily accessible area it would probably still be a pain to keep the tool on the fitting...especially at the right angle. In addition the grease can get pricey so I wouldn’t want to spill any for no reason. As it turns out it isn’t hard to get to the fittings, but keeping linear pressure on them would be a real pain - especially without a lift. This little bad boy makes things amazingly simple, heck for some of the fittings I don’t need to remove any parts - just need to have enough room for the part to fit and you’re golden. Line the coupler up, press down and lock it onto the fitting. Then you can leave it alone and just operate your gun. It was effective to the point that I wasn’t sure if grease was making its way through until it came out of the bushing. I’ve never done it the old fashioned way, but this seems like it’s worth at least 5-10 min per fitting (for a newbie mechanic working in their garage). That alone justifies the price to me. I sent this to a couple friends I know - a mechanic and a friend that grew up on a farm (and uses the farm shop to do their work). They both instantly spent the $30 and bought it. To me that validates the price/value. Combined with the fact that it works as advertised I’d say that this is a great buy. Don’t regret almost doubling the cost of my grease gun for it!