- 3D printer motor with high torque

- 59Ncm(83.6oz.in) holding torque

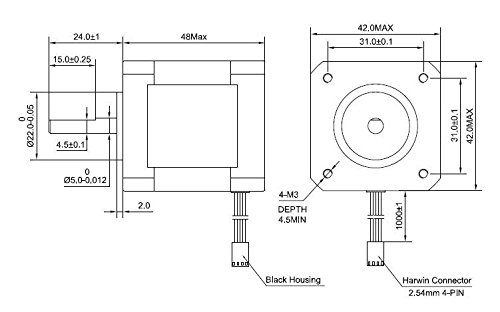

- NEMA 17 bipolar 1.65"x1.65"x1.89" 4-wire

- Build with 39.37"( 1m) Cable and 0.1" pitch Connector

- Rated current 2.0A & resistance 1.4ohms

-

Information

-

Twitter

-

Pinterest

-

Youtube

-

Facebook

Carmen Spasevski

Perfect shipment packaging.

I received a 0.59Nm(5.22lb.in) = 59Ncm(84oz.in) delivered in remarkable packaging. I have not used it yet, but I have no doubt it will operate perfectly. In fact I'm confident I could tape it back up and drop it from the 4th floor onto black top and it would perform just as well.

Amílcar Teixeira

STRONG for Nema 17 See wiring instructions and other myths dispelled below

VERY powerful for NEMA 17. The old Nema 17 I had was a toy so, I was prepared to redesign for a Nema 23, but that was totally unnecessary. This motor is legit and could likely drive all manner of 3D printers, CNC Routers, etc. I drove this at 36 volts and 1 amp and it remained warm, not hot. DISPELLING MYTHS: WIRE COLOR IS ALWAYS MEANINGLESS (other reviewers have probably learned this by now): To determine pairs, spin the shaft. Touch two wires together spin again - if it is more difficult to spin, that is a pair. The other two are the other pair - VERY simple. It is not uncommon for motor wiring color to be MEANINGLESS. Also, if you take you motor apart, you likely ruined your motor. HEAT IS OK: I see a lot of hysteria about heat. Essentially the motors can get very hot and it is ok. If you cannot leave your finger on it for more than a second without burns - then it is too hot. CHANGING SPIN DIRECTION: Flip ANY SINGLE pair. The motor will turn in the opposite direction. If you flip both pairs it is likely nothing will change. If you swap pairs, from A to B, direction will also change - but you only need to flip a single pair to effect a change in direction.

Lucky Day

and I am both surprised and pleased at how well they run this rather large machine

I've converted an old radial arm saw to a CNC router. I'm using three of these steppers, and I am both surprised and pleased at how well they run this rather large machine. Lots of torque. I'm running them with A4988 drivers at the full 2 amps, on a 19.5 volt power supply. They are turning T8 lead screws with 2 mm pitch. I could get more top speed by using a 24 volt power supply, but so far they work great ... have never stalled or lost steps cutting 3/4" MDF with 1/4" straight cut router bit.

Chantal Finn

Great stepper motor for my DIY dolly-zoom project.

For videography the hot thing is panning the camera during a video shoot. To accomplish this smoothly I mounted a STEPPERONLINE 59Ncm motor to a skateboard with a cog belt and sprocket set (Amazon). This was a big success because it was easy to control direction, distance, speed, etc. using an Arduino UNO and the BIQA A4988 stepper driver (Amazon).

Mckenzie Glass

Powerful, solid stepper motor

These motors are very powerful. I'm using them for a motor drive camera mount and they have plenty of power with just a 9.6 volt battery from my Makita drill. The connection wires are plenty long, so you don't need the electronics right next to the motor. You do need a stepper controller that can handle the current load, but inexpensive controllers are readily available and easy to connect. I am using an Arduino board and the Qunqi L298N Motor Drive Controller Board Module Dual H Bridge DC Stepper, which has good heat sinks to dissipate the heat.

John Case

Plug and Play for Prusa i3 3D printer

I needed a new motor for my Prusa 3D printer. It was skipping and erratic in Y axis movement. After isolating motor failure as culprit (by switching X/Y motor inputs on the raspberry pi motherboard of the printer and observing failure of Y motor with X commands but working X motor with Y commands), I decided that a cheap trial would be to order a new motor and hope that fixed the issue. Got it next day and simply unplugged the old Y motor lead and plugged in this new one via its attached clip. Worked well through the manual command movements (no adjustments to the 4 wires' position needed for me), so I fished the wiring through (wire length sufficient) and replaced the motor bolted on. test print was dead on, so I wrapped and zip-tied the wiring back in place. Slightly longer than the stock motor so I adjusted the Y-belt tensioner (at the front of the machine) to proper alignment. Many prints later, I am very happy with performance. All working as new. This is the great thing about open source hardware.

Jackie Fitch

Strong motors at decent price

Strong NEMA 17s. I put together a very kludged up CNC using 3 of these. They have lots of torque. Of course, I'm using 18TPI threaded rods as the drive, so that trades off speed for power. In any case, these are working great in my setup (arduino UNO clone running GRBL, with a CNC shield, populated with DRV8825 stepper drivers). The 4 pin connector on the motor plugs directly into the CNC shield, so that was a plus, not having to cobble up connectors. The leads are fairly long as well, didn't need to add extensions either.

Endia Wilson-Evans

best iv'e tried so far and brought a second lot

i originally got nema 17 with 8mm thread built in but they had not enough tork and would slip alot, thought id give theses a try and instant improvement, abit longer than standard motors so check they will fit but are still the standard 40x40mm top and bottom Update. these are so good, i just brought 2 more, so much less heat caused by these motors, barely warm compared to the others, i even lowered the ampage and have more torque if you need more torque, cooler motors and lower voltage to keep motor drivers cooler then these are definatly worth a try, will need 4 more for a delta build and these are the ones i will be using, so much better than the others

Nancy Reis

Replaced my Prusa i3 MK3 extruder motor and it's perfect.

The stock i3 mk3 extruder motor gets VERY hot. I don't know if it's poorly wired or just constantly overtaxed, but there's concern that the heat will travel down to the bondtech gears and deform the PLA as it's feeding. Since I was having some random issues, I decided I'd swap out my extruder for a slightly more powerful one, and this is the one I chose. It's a tad longer, but even with the newer R3 mods, that makes no difference in mounting it. It's a perfect replacement. It stays cool even for 12+ hour prints, and it hasn't given me a single issue. A perfect replacement.

Ava B Maistry

I am now a fan.

Not sure i believe the 84oz inch rating...doesnt seem that strong, but other than that, it worked great. Addendum: Just bought 3 more of these motors and I am now pretty impressed with the product. My main printer is getting a little "long in the tooth" and the X axis motor would get very hot and recently started slipping (missing steps) about 10 minuites into the print. I replaced it with one of these and it not only stayed relatively cool, it never missed a beat. My prints seem to be much beter which tells me that my old printer was slipping even when I didn't think it was.