- SOLID SOLDERLESS CONNECTION: Handy tool for a firmly stable connection,no need to solder.

- FIREPROOF MATERIAL: Made from fireproof material, high temperature resistance. And the plastic is thick and solid, which is hard to be broken.

- APPLICATION: Fits all 10mm 3528/5050 wide RGB LED strips. Perfect for LED tape DIY project, compatible with both waterproof and non-waterproof light strips.(Please peel off silicon on the surface around soldering area when installing waterproof strips )

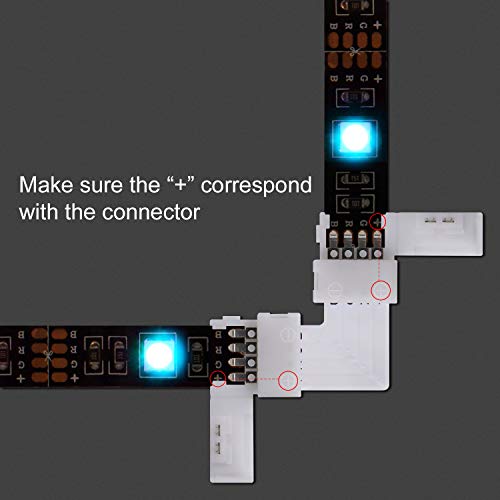

- EASY TO USE: The L Shape 10mm 4 Pin light strip Connector is easy to install. Simply slot the strip light into connector and clamp the cover (no need to solder). Ideal for right angle corner strip connection.

- 100% SATISFACTION GUARANTEE: We strive to provide each customer with the highest standard of customer service to ensure you have a pleasant shopping experience. If you have any issues, inquiries or need assistance, please feel free to contact us directly. 30-day money-back guarantee for any reason, 12-month warranty for quality-related issues.

-

Information

-

Twitter

-

Pinterest

-

Youtube

-

Facebook

Kera Presentandfuture Wilson

They work

Good to go on the back of my monitor. When using these keep in mind that there is a channel, small tabs, to slide the connector and light strip in the lock. My light strip was dome shaped so I had to cut the protective coating back some by splitting it from the strip under it and trimming the coating with a scissor to the first resistor to lock it. I did sacrifice one light on each run to get the most of the copper contacts. One thing to keep in mind, as long as your positive on the strips to the connectors match, on my run it was to the outside, the RGB does not matter. These are just a connector. My strip kit was from Amazon, and as you can see from the pic, my strip from input was +GRB.

Lynn Vanessa Isaac

These elbows are good and the connectors bite into the led strips which ...

These elbows are good and the connectors bite into the led strips which is nice because it keeps them in place. But I dont understand why if you reverse the strips but keep the led leads in the same orientation it will not work unless power is to power on the elbow. So if you need the elbow to turn the other way you will need to look at the back of the elbow.

Chickoo Fredz

Five Stars

Perfect for solderless jobs. Work as expected.

Katie Lopez

Snap Snap Snap, click and done. Simple and quality

I did a custom LED lighting project for my entertainment center. I thought, "shoot I know how to solder what do I need this for..." Well, I am glad my friend had me spend the extra $5 and get these to go with the kit. I can't tell everyone how simple this made the process. These are made of a strong plastic that makes them stiff making sure it holds the connections. It has simple small guides in the clips to make sure the strip being inserted is flat which makes it easier to slide under the metal clips. The snaps are a little difficult to get open if you don't have something flat or nails. I bought my wife lunch and had her open them all. If you are debating thses on an install I say DO IT!

Zack Ael

Instructions

I was having a hard time figuring out how these connect, the biggest problem being that the clips are so small, I had trouble seeing them. First, the hard white plastic pieces opens, they have a cover that’s opens and closes, the side that opens looks like a small box, pulls away and flips up. Obviously the best way to get these open is to use your teeth. Once you have both sides open you’ll see 4...very, very small Silver prongs, the trick is to slip either the corner piece or the cut end of the LED strip pushed UNDER the Silver prongs. If you look very carefully at the side of the plastic piece with the top open you’ll see a very small grove, the cut end needs to be inserted into this grove and pushed in UNDER the Silver prongs. The 12v, Red, Green, Blue must match, your completing the circuit to get the next string to light up. Hope this helps.

Marsha Robinson

Wonderful connectors, Very High Quality

Great connectors! The led strips just slide right under the connectors and snap down nice and tight. I wish all of the products that I purchased for this project would have been this high of quality my Friday night and Saturday afternoon would have been a whole lot nicer! Thank you for offering such a good quality produce

Saba Faheem

Great Strip, but needs to fix the sticky.. There is a solution

I just recently purchased a 71" sti/stand desk and decided to put a LED strip underneath. I purchased this product and I am very happy with it and it works well. I knew going in not to use the sticky side as it does not hold up. so I purchased the Strip Light Mounting Clips (https://www.amazon.com/gp/product/B079LZSRXV/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1) and they work wonderfully. The lighting strip fits perfectly in them. The strip itself and be cut in its specified area to fit your needs. Will purchase again when needed.

Tyana Smith

Good connectors for 90 degree turns.

Worked just as described. These come in separate pieces (connectors and the strips) so you have to piece them together. This is actually a good thing as it takes about 5 seconds to snap them in and allows you to interchange the parts of some are defective. In implementing these, I encountered a few defective clips but the purchase provided me with more than what I needed to complete the project so it worked out well. The only thing I would have like better would be small pieces of double sided tape to help with the mounting. All in all, this was a good product and I would definitely buy again.

Jody Carney

Quick And Easy

the are great for those whom are DIY and working for tape for the first time or whom don't have access to a soldering iron/not confident in your skills. these ones seem like the usual quality, nothing wrong or bad. all the printing on the tape portion was in place. two tips with these: 1: they won't work properly anywhere the tape has been solder spliced or the tabs have solder on them. they will be too thick to fit into the plastic clips of the corner. but that is the case with all these clip style connectors usually. 2: as a ProTip, the tape potrion of these without the plastic connectors are a wonderful way to have clean corners on pro level installs. as long as you can do what you need in the standard tape second lengths these look better than leads for a corner and are faster to do, no wires to strip, tin, solder.

Anita Samui

Great 90* couplings for LED Tape lights - SEE SAFETY ISSUE

There is not much really to say about these -- they work with all standard LED tape lights. There are some things you need to be aware of: If you are using the rubberized waterproof tape lights, you will need to CAREFULLY strip back some of the rubber coating in order for these to work.I used a sharp single edged blade and cut straight down and was able to peel it back. Also, do a dry-run on a table with connectors and such on a table before sticking them to the surface. All the wires need to match all the way through and the connectors will FIT in both orientations, but only one will work. These are well marked and will facilitate proper connections. EDIT: 8 months after installation, there was a small electrical issue. See attached photo. Over the course of a week or so, I noticed that the lights on one side of the junction were flickering, then eventually turned off completely. Upon investigation I learned that the connector had burned up. I am leaving the rating where it was initially as this could have been installation error that took time to manifest.