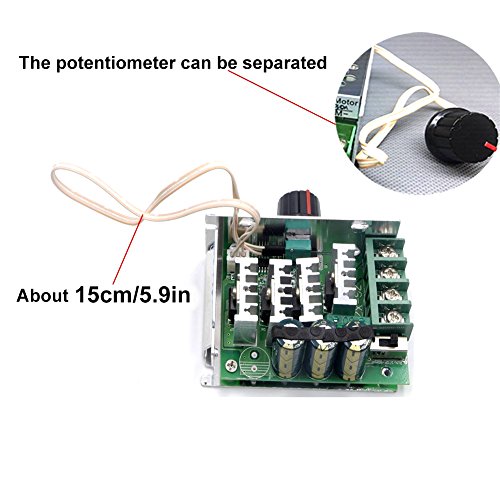

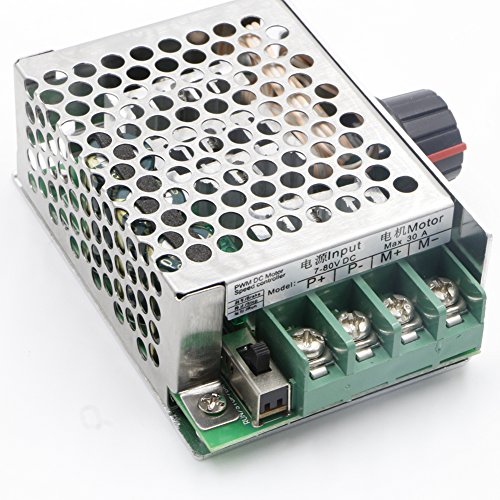

- Potentiometer cable(about 15CM) can be separated, with running stop brake function

- Suitable for long hours of work:Circuit optimization design,stable

- Adjust the motor smooth no noise no vibration,with power indication,wide duty cycle adjustment range

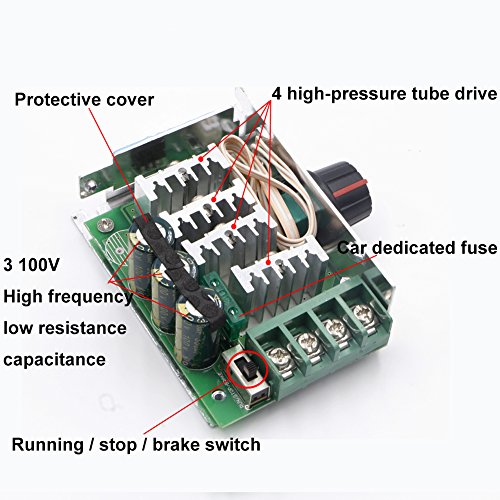

- Using imported high-voltage MOS tube, three pressure 100V high-frequency low-resistance capacitors, automotive fuses

- PWM frequency: 12KHZ

-

Information

-

Twitter

-

Pinterest

-

Youtube

-

Facebook

Dawn Scholl

Good Stuff at a Fair Price

Sometimes you get burned ordering electronics from China. This little joker works perfect on my Harbor Freight mini air compressor/tire inflator. It's rated a little higher than needed, so I should hope so, but you never can tell. Been working well for months now.

Maryann Burton

Perfect for my LED strip

I bought an LED strip, but it didn't come with a power supply or a dimmer, and I wasn't about to get ripped off on dimmer switches and fancy power supplies. Therefore, I bought this PWM controller and a 12 V power supply (also under $20) to power and control my LED strip. This controller seems very efficient and generates minimal amount of heat for my application. Although turning the potentiometer knob down to the end doesn't turn it off completely, this controller has a switch on the side you can use to fully turn it off, so it works for me. This controller should also work well for controlling the speed of a DC motor.

Hilario Castrejon

Works like a champ!

I put together a denitrification reactor to grow anaerobic bacteria to lower my nitrate levels. In order to do that one needs to create an environment that is deficient in oxygen with suitable media for the bacteria to grow in/on. This requires reducing the flow of water to below 50gph. I set up this little system using Seachem De*nitrate, two fishes 150 reactor, a simple fountain pump rated @ 63gph, a dc motor control circuit to adjust the speed of the pump, and a dc power supply. The thing was simple to hook up and is working like a champ!

Suresh Gorrela

power controler

use the power supply for my Christmas displays and the work great

Chris Smith

RioRand 7-80V PWM Motor Speed Controller

This RioRand motor speed controller worked out perfectly for my 24 lb thrust watersnake trolling motor. I was able to remove the ribs in the white upper half and attach the controller with one screw and nut to mount the unit to the upper inside half. The 11 1/2 inch wire to the control switch was then run thru the handle and attached to the front of the trolling motor by drilling a 5/16 inch hole in the end of the handle. I did cut off the inside of the handle and left about 4 inches, but the handle is flush on the outside. The controller was easy to wire inside the head by cutting the red and black positive and negative wires that run to the battery connectors. Just attach these to the unit as shown. I also cut 10 inches off the shaft to use inside and Hobie drive.

DonnaMae Zurbano Gutierrez

Works !

Needed to control speed for 30lb thrust trolling motor, 0-3 mph, for fishing Kayak. Also with purchase bought (2) 10 gauge CSE 2 pin quick disconnect harness to splice in switch between 12v marine battery and motor. Used marine grade shrink tubing and had to file down metal terminal connectors to fit terminal slots.

Jacinda Lynn Walker

Fast shipping

Works as advertised, used with 24v motor

Lauren Gilliam

It appears to be sturdy

This controller works perfectly ,i like the fact that it has fuse protection . I am using this to control a small 7 in raditor fan under the seat of my pioneer 1000 . I have wired after the controller a double pole double throw switch to change direction of fan ,to such heat from engine or blow to remove heat from engine compartment

Su San

Fused- a great thing!

I ordered this to replace a slightly more expensive one with more rated amps but no fuse. The fuse blew on this one and now I know the motor was bad. When I get the new motor I will know if the fuse saved the controller. I hope so!

Brenz Siringan Fenomeno

The adjustable speed knob is removable. If you take ...

The adjustable speed knob is removable. If you take it apart, you can put whatever speed controller you want on it. My 5k was not compatible. Not sure what the pot is actually rated for yet. I think 10k.