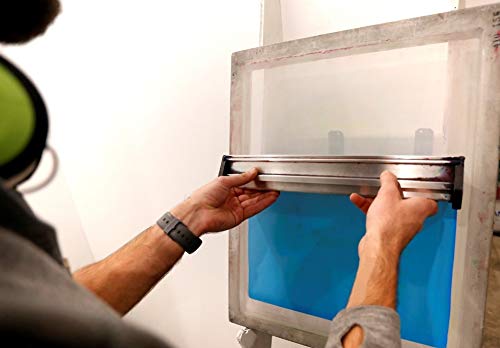

- All Purpose Emulsion That Works with Plastisol, UV, & Solvent-Based ink systems. Excellent print definition. Durable for long print runs. Virtually Pinhole Free

- AP Blue must be exposed with a UV LED light source- If you do not have a proper light source please use our TEX-Blue which is beginner friendly

- No mixing is needed ready to use Emulsion, when working with Water Based inks it is recommended to add diazo to prolong life of image.

- For best results degrease/dehaze your screen before printing with Hyper Haze. And use our Ecotex Emulsion Remover to reclaim your screen.

- Do not use this emulsion if your using a LED Black Light or White light needs to be a proper exposure unit

-

Information

-

Twitter

-

Pinterest

-

Youtube

-

Facebook

Kaitlyn Shepherd

I have purchased multiple times already

My favorite emulsion it lasts a long time

Fiona Mullins

A great buy!

Everybody else must be doing something wrong. But it works WELL! A thin coat on my screen. Let dry overnight. Expose to sunlight for 15 seconds in full sun or upto 1 minute in heavy overcast. Wash it down. Image falls right out. Hit it with hardener if using waterbased ink and your good. 1 pint should coat 50 - 60 16x20 screens.

Becca Sisson

Good stuff

Love this product

Graham Brown

No additive needed

Dealing with emulsion can be nightmare-ish; stay correct on your burn time/light strength/distance numbets, and blue will take care of yo.

Jeremy Waugh

Easy one-step emulsion.

Product arrived on time and works great. Very easy to use.

Phea Roun

Love this stuff

Love this stuff. dries fast, burns quickly, washed out clean and lasts forever (so far I haven't needed to remake any screens) This quickly has become my go to Emulsion.

Mary Cox Morris

GOOD EMLUSION! IF YOU PREPARE IT CORRECTLY BY...

This product is very good. No diazio to add and ready to use. I had many people ask me how to properly use this product because they always get over exposed or under exposed for their high detailed halftone transparencies. I use 2 and 2 coatings and letting it dry in a WARM/Ventilated dark room WITH NO HUMIDITY (Invest in a dehumidifier) Usually I'll let it completely dry for 4 or more hours. When it comes down to exposing your film positive; I recommend using a exposure calculator FIRST! There's free ones online you can download. I use a 500w halogen work lamp; 16 inches away from screen and film. With 50 pounds of pressure "sandwiching" the screen and film positive with a solid flat board on a piece of glass or anything clear and flat that'll hold pressure well. After exposing spray your exposed screen with water (I use a water spray bottle) and drench it. Repeat again a min or so later. Your image should be coming out by this time so do a wash out.... it should melt out like hot butter with no lose of halftone detail.

Nerwin De Vera

Great product!

I am a new screen printer, and just starting out learning the ropes. This emulsion was easy to apply and I loved that I didn’t have to do any mixing! I spilt half my jar on accident, so that’s a big bummer and still trying to get the burn times correct, but overall I am content with my purchase and will buy more (sooner rather than later to due my clumsiness!)

Neena KN

Definitely all purpsose, easy to use!

This worked great. It was my first time screen printing in 20 years. With a nice thin coat the screens dried in couple hours. Being a DIY type person, used a 150 watt clear bulb for 45-55 minutes at 12 inches. The exposed emulsion held fast as the remainder washed out with ease. I got great, fairly detailed, prints from them with speedball ink. As the description states, it is pre-sensitized, so coat and dry in a dark environment.

Azura Ena Rhosyn

Good product

Love it