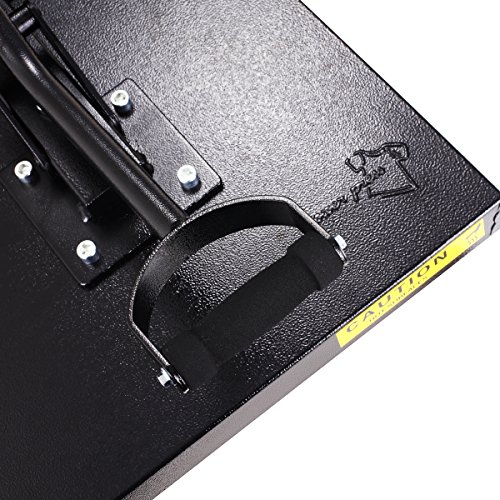

- Brand new, 15x15heat plate. Voltage: 110V. Power: 1400 w

- Replaceable fuse: protect machine from overheating and electric short

- Teflon coated heating plate: don't need coated sheet anymore, harmless to the cloth, convenient to clean, and provide attractive appearance

- Lcd control board: fully digital temperature and time control. Temperature range: 0-450f time range: 0-999 s

- Individual safety control chip: precisely control the plate heat on the setting degree. The heat plate temperature will be stable during transfer working. The only brand has this safety insurance, buy yourself safety

- If you have any question, please feel free to contact us

-

Information

-

Twitter

-

Pinterest

-

Youtube

-

Facebook

Shauna P Green

So far it works great!

Arrived a lot sooner than expected. The only problem I have is it is hard to open, once you set your pressure to where you need it to be. We took it outside and turned it on the first time, it did have an unpleasant smell you would not want in your home. We let it run for about 30 min and I have not smelt it again. So far it works great!

Susan Jordan

great value! fast shipping

I used these to make heat transfer pillows. I bought the 1/2 inch foam at Joanne''s and sewed these together! I made two 12x12's all the ones you see in the pic, and I have one sheet left over! I'm happy! :)

Elizabeth Navarro

Overall great press. I printed about 20+ shirts today with ...

Bought last week and just used today. I am new to using a heat press but things went well. I did unbox it the day I received it just to ensure it was the right press and to check if there were instructions as other reviews have emphasized that there weren’t any. I can confirm are no instruction. However reading question and reviews on Amazon along with a couple of YouTube videos helped me out. Just a couple of things to keep in mind. 1. The outer material including corners of the top plate do get hot. 2. To heat up the press you will need to open up the press, mines beeped continuously until I did which I learned from a video/review 3. After setting the temp or time you will probably need to hold down each applicable button for a min to ensure whatever you changed is set. Ex. after using the up/down button to get to the desired temp, go back to the temp button and hold it down so it “sets”. 4. I did plug the press into a surge protector as others complained about their circuits tripping due to the amount of electricity the press use. Overall great press. I printed about 20+ shirts today with no issues P.S. my suggestion is to purchase Teflon sheets as this pres. did not come with any.

Zilan P Nhene

Perfect for many things

Although there are many uses for these and I'm sure I'm going to.take advantage of several, I ordered these to use with my HTV and my heat press. I prefer Teflon for my vinyl craft projects and these did not disappoint. Pliable but heavy duty, the stock up amount included means I don't have to constantly order, but my favorite feature is the SIZE. The 16x24" size they came in is PERFECT for my larger quilt vinyl projects so I don't have to keep moving a smaller sheet around the area - GOOD COVERAGE. Have also used to protect my quilt pieces pressing and iron-on printables so far. Have used one sheet so far multiple times and it's still in great condition showing little wear (as seen in photo) and appears to have many more uses in it.

Rotica Pickens

Best we have tried!

We have purchased several different heat press machines in the "under $500" category. This by far has the evenest temperatures across the top plate, tested with a laser. The silicone on the bed has nice rounded corners that shirts do not get stuck on, yes this really is a thing when you are doing high volume! In the last 3 months, this shirt has pressed a successful 2500+ shirts without issue. One problem we had was getting the pressure right as the user only has a knob to turn and no real good way to set "60psi". Our learning curve and solution: #1 Discovering that the handle will "pop" into place, and keep the pressure on the shirt. If you are having to hold it down, you are doing it wrong. Adjust the knob on the top back. #2 Adjust it to the "hardest" point for the operator to press the handle down so that it clicks into place. This is maximum pressure, and is good! #3 When releasing it, be QUICK! It will pop up a lot better for a "quick yank" than grabbing it and trying to lift. The swiftness will help the handle pop up and release the shirt out of the press. What we discovered WE needed to operate at high volumes. (This is OUR setup based on shirts and transfers we use.) #1 The press, adjusted for max pressure. #2 Teflon sheets, only if doing transfer to both sides of the shirt. (use the sheet between the shirt and the silicone bed, so your first print doesn't stick. Don't forget to let the 1st transfer fully cool before doing the 2nd.) #3 Plenty of power, when you get 3 of these on the same 15A circuit, it will blow! lol #4 Sturdy table and room to work. We work with 2x 8ft tables. Table #1 Shirt press(s) with a stack of shirts and transfers for easy access. Table #2 directly behind the operator(s) for cooling, folding and boxing.

Michael Lynch

These sheets will save your iron!

These were perfect. Came in a package of 6... so you can share with your friend. I use for quilting and it totally protects my material and my iron, which is important to prevent glue from ruining my iron. The Teflon sheets do not get hot. I highly recommend!

Jody Fick

... my machine for 2 years and it still works great. I haven't had any issue with it

I've had my machine for 2 years and it still works great. I haven't had any issue with it. I turned this machine from a 260.00 invest to now earning over $8,000.00 monthly. Time to purchase another.

Aalia Bhat

Great Press

I'm a first time shirt maker for my llama hiking business in the Smoky Mountains. I researched presses on the market and this came up as one of the best yet the ratings on Amazon don't reflect it. I was not sure on purchasing this press because of the reviews that people have posted on Amazon. I figured for a couple hundred bucks it was worth the gamble. I took it out of the box and it had instructions (read where some presses do not). I purchased some transfers and t-shirts already and started pressing the first day. I have pressed over 200 shirts so far and has worked flawlessly. I only had one mistake and that was because I rushed and the press was not hot enough yet when I pressed on a transfer. I was thinking that a swing arm would be helpful because it moved the hot plate out of the way while you put the shirts in their position...I found that I was pretty good at situating the shirt just right without getting burnt. I would purchase another one if I had to. Hope this was helpful to someone.

Valinte Jesza

Great product and even better customer service!

I never leave reviews. I am just the type of person that doesn't ever log back on to leave a review but I felt compelled to leave one for this. I purchased this heat press in August of 2018 for my wife to do some light work around the house with it, make us some custom shirts and things like that. We didn't use it very heavy or frequently at all. Well, about a week ago, I was in the middle of pressing a shirt and the handle popped back up and the unit wouldn't stay closed. After some fighting with it and closer examination, I noticed that the handle was bent and the tubular bar actually split open and caused the unit to not be able to latch anymore. I am not sure if this happened in transit or if I just got a bad unit (these things happen). I immediately reached out to the supplier, sent pictures and all relevant information, and they responded to me right away, even during their holiday!!!! If that is not amazing customer service I don't know what is!! We exchanged a few messages and the company ended up replacing the machine for me! I cannot even begin to express how thankful I am for that level of customer service as it is very hard to find these days. I plan on ordering another heat press soon and I can guarantee that I will be coming right back here, as well as recommending friends and family as well. Thank you again!! -Mark C.

Lori Ann Whitaker

Love my new press! A little tricky to operate until you understand how it works.

I use this press iron to make custom made shirts. It works great! I read all the reviews before purchasing it and the bad reviews seemed to come from lack of knowledge. Look at your breaker box. It must be plugged into an outlet with 20 amperage and not 15. Otherwise the lights will blink and something may get electrically fried. Also once the desired heat is reached one must press the temp button again. I'll soon do a video and you may check it out on my YouTube channel broke in Georgia.